Micro Injection Molding/µ-MIM

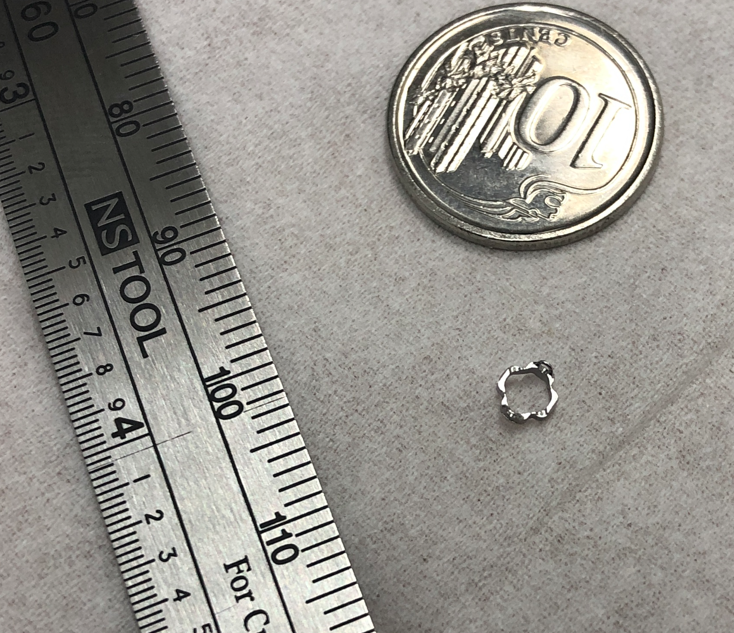

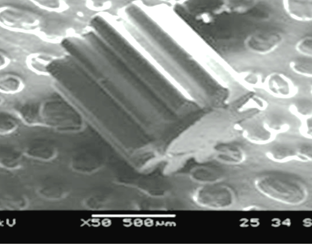

Micro-Injection Molding is a molding process for the manufacture of metal parts, which can create intricate components on a micro scale. This process can achieve tolerance of up to +/- 5µm, as well as parts weighing as low as 0.01 grams.

This molding process permits the manufacture of complicated micro components that possess small geometries. Micro MIM can be performed with higher accuracy and precision compared to traditional injection molding methods.

Advantages of Micro Molded Parts:

- Less expensive process compared to Micro Machining or Plastic Injection Molding.

- Faster cycle time to produce part at high volumes compare to Micro Machining.

- Higher precision compared to MIM, with tolerance of up to +/- 5µm.

- Super-fine surface finishing with as-sintered process.

- Lower cost and high volume production.

Industry Applications Micro Injection Molding Offers:

- Medical devices such as minimally invasive surgical instruments.

- 5G mobile with micro gear components.

Discover Micro Injection Molding Manufacturing Solutions With Dou Yee Technologies

Dou Yee Technologies has the manufacturing capability needed to provide advanced Micro Injection Molding solutions and take your production to the next level.

Dou Yee Technologies provides services worldwide, including direct coverage in Singapore, Germany (Dusseldorf, Stuttgart, Frankfurt), and the US (California, North Carolina). We also extend our services to many other countries and regions across the globe. Contact us today to inquire about how we can assist you, wherever you are located!Contact us today to inquire about our services.